Acquisition and Manufacturing

A potential increase of 40% revenue and over 1300 skus.

Case Studies

Business Issue

A Flow Consulting client recently acquired its number #1 competitor, leading to a potential increase of 40% revenue and over 1300 skus. Our client concluded that they did not have the skill set and internal resources to effectively manage the manufacturing move and business integration in the tight timing of four months.

Approach Used

Flow took a unique approach and provided two Flow consultants to function as an equivalent full time Business Project Manager. Their charter was to facilitate not only the business integration and start-up, but also to coach and develop the organization to understand and implement lean strategies that would enable them to be able to meet the expected 20+% business growth in the next 12 months.

Key milestones and activities of the project included the following:

The Flow consultants began by facilitating a two-day workshop to develop the project plan and required resources.

Led the team through a DMAIC approach to ensure the team’s comprehension of the opportunity, project scope, infrastructure risks and the metrics to insure stability.

Recognized additional manufacturing space was needed.

Facilitated a four day workshop to design the layout of the product line using lean principles.

Multi-state relocation of internal sales’ group and adaptation of existing processes to meet new requirements.

Updated and transferred all customer care processes.

Updated and transferred external sales business processes and vehicles.

Updated and transferred engineering and marketing documentation and information.

Transferred the internet global domain.

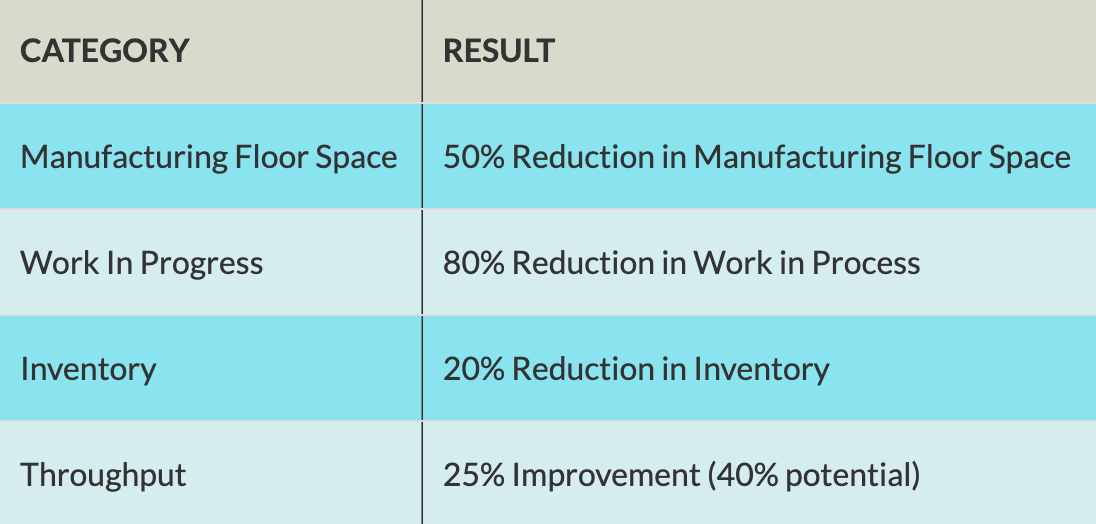

Results

The company successfully upgraded its ERP system, obtained and refurbished a new building for lean operations, moved all equipment, inventory, and started up manufacturing in its permanent new location 1300 miles away within the targeted time frame.

The internal team demonstrated within weeks that they were able to execute 40 systems a week — exceeding original goals. During the move the customer demand unexpectedly increased 30%, and the manufacturing team demonstrated that it had the capability to eliminate past-dues in 6 weeks.

Key Metric Summary: