Slow Manufacturing Cycle

A 27% reduction in direct labor and a 53% reduction in cycle time.

Case Studies

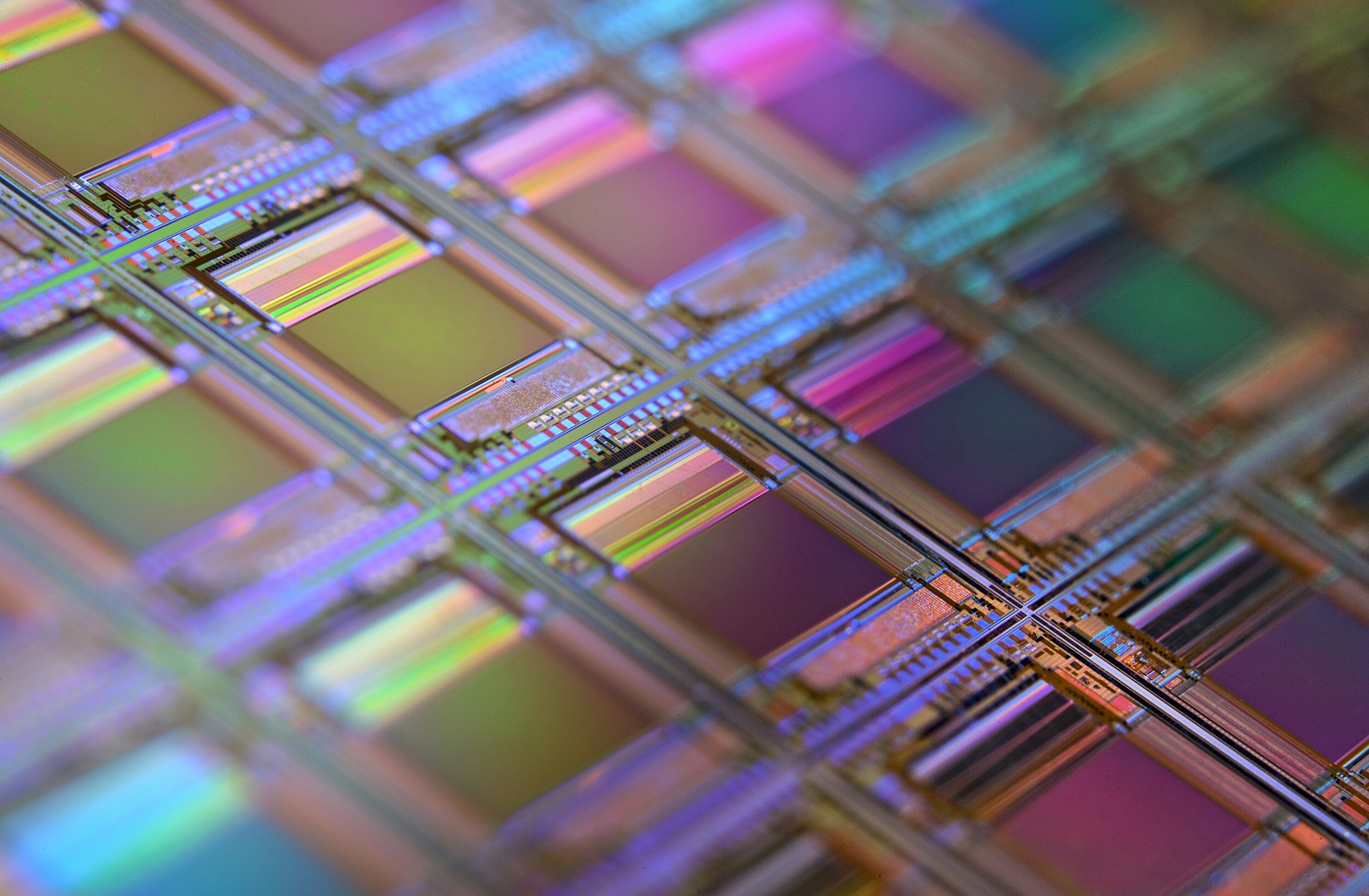

Business Issue

Microchip test equipment manufacturer was experiencing high product costs and delivery cycle times exceeding customer expectations.

Approach Used

Flow consultants implemented comprehensive leadership driven “Lean Enterprise” principles and a series of kaizen sessions with both exempt and hourly personnel.

Results

The company achieved:

A 27 percent reduction in direct labor.

A 53 percent reduction in cycle time.

A 59 percent reduction in required floor space.

A 38 percent reduction in defects found at test.